L’Union européenne porte les obligations de diligence en matière d’approvisionnement à un niveau très élevé grâce à une nouvelle loi visant les grandes entreprises. Les changements sont conformes aux lois adoptées sur d’autres territoires. Toutefois, la nouvelle loi de l’UE, baptisée » Directive de l’UE relative à l’obligation de diligence raisonnable en matière de droits de l’homme, d’environnement et de bonne gouvernance « , est plus complète que ce que l’on a vu jusqu’à présent. Elle devrait entrer en vigueur dans les 24 prochains mois. L’objectif de cette loi est d’aider à passer d’un régime volontaire à un régime de lutte contre l’impact négatif des activités des entreprises au niveau mondial. Selon les résultats des recherches menées par l’UE, seule une entreprise sur trois fait preuve de suffisamment de diligence dans ses chaînes d’approvisionnement. Cela justifie donc la nécessité d’adopter une approche réglementaire en la matière.

Nouvelles exigences de la législation européenne en matière de chaîne d’approvisionnement

La nouvelle loi concernera les grandes entreprises qui emploient plus de 250 personnes, dont les actifs dépassent 43 millions d’euros et dont le chiffre d’affaires est supérieur à 50 millions d’euros. Elle s’applique également aux entreprises proposant des services et des produits financiers. Les institutions cotées en bourse devront également s’y conformer. La loi exigera des entreprises qu’elles s’attaquent aux menaces potentielles pesant sur les droits de l’homme, l’environnement et la bonne gouvernance dans leurs chaînes de valeur. Elles devront communiquer leur approche dans un document de stratégie de diligence raisonnable. Le projet de loi détaille ensuite chacun des trois domaines de la diligence raisonnable, à savoir

- Les questions relatives aux droits de l’homme englobent les questions syndicales, les droits du travail et la protection sociale des personnes vulnérables.

- La diligence raisonnable en matière d’environnement concerne le traitement des déchets, l’utilisation des ressources naturelles, la pollution, la déforestation et les émissions.

- La bonne gouvernance implique de lutter contre la corruption et l’influence indue.

Les entreprises devront examiner de plus près toutes les étapes de leur chaîne de valeur. Ainsi, elles devront vérifier que tous leurs fournisseurs et sous-traitants respectent les réglementations et les exigences ESG.

Qu’est-ce que la transparence de la chaîne d’approvisionnement?

L’appel lancé aux entreprises pour qu’elles fassent preuve de diligence raisonnable dans leur chaîne de valeur et qu’elles en rendent compte vise à accroître la transparence de la chaîne d’approvisionnement. Bien que le concept existe depuis un certain temps, la compétitivité d’une entreprise aujourd’hui pourrait très bien en dépendre. Le consommateur d’aujourd’hui est plus soucieux de l’éthique qu’il y a dix ans. Aujourd’hui, la transparence signifie connaître et communiquer les détails opérationnels de la chaîne d’approvisionnement aux parties prenantes, y compris les clients et les investisseurs. Les entreprises sont traditionnellement plus ouvertes à la visibilité de la chaîne d’approvisionnement qu’à la transparence. La visibilité de la chaîne d’approvisionnement se concentre sur l’analyse de la chaîne de valeur afin que la direction comprenne les points à améliorer. La transparence, quant à elle, est destinée à l’établissement de rapports externes. Il peut s’agir d’une entreprise coûteuse en temps et en argent qui peut révéler des problèmes exposant l’entreprise à la critique. Toutefois, lorsqu’elle est bien menée, les avantages potentiels l’emportent largement sur les inconvénients.

Les avantages de la transparence de la chaîne d’approvisionnement pour votre entreprise

Quels sont les avantages d’une transparence accrue de la chaîne d’approvisionnement ? Voici quelques-uns des principaux facteurs de valeur :

Assurance client

- Aujourd’hui, les consommateurs veulent savoir comment sont fabriqués les produits qu’ils achètent.

- Dans certaines catégories, comme les produits alimentaires et les produits de soins personnels, on souhaite obtenir des informations détaillées et la preuve que les pratiques d’approvisionnement en matériaux ne nuisent pas à l’environnement ou aux communautés.

- En recueillant et en partageant des informations sur la transparence, une entreprise peut répondre à des préoccupations sociales, religieuses, éthiques et environnementales et permettre à ses clients de faire des choix éclairés.

Fidélité à la marque

- Le partage d’informations avec les clients est essentiel pour instaurer la confiance et la fidélité à l’égard de votre produit.

- La transparence aide les consommateurs à faire des choix éclairés.

- Si les valeurs et les pratiques d’approvisionnement d’une marque sont acceptables pour un consommateur, celui-ci devient fidèle à la marque parce qu’elle s’aligne sur ses valeurs.

- 75 % des consommateurs âgés de 18 à 40 ans sont prêts à payer davantage pour des produits qui correspondent à leurs valeurs, selon Nielsen, une société mondiale d’études de marché.

Un impact plus important

- Lorsqu’une marque s’engage à respecter les objectifs de développement durable tout au long de sa chaîne de valeur, elle doit tenir compte des pratiques en matière de droits de l’homme et de droits du travail, de la diversité et de l’intégration ethniques et de genre, de la conscience environnementale et des systèmes de gouvernance de ses fournisseurs.

- En communiquant les attentes de la marque et en travaillant avec des entreprises qui partagent les mêmes valeurs, il est possible de créer des partenariats qui permettront à la marque d’obtenir des résultats supérieurs à ceux qu’elle obtiendrait seule.

- Les partenariats dans la chaîne d’approvisionnement offrent des possibilités d’amélioration continue pour renforcer le contrôle de la qualité, la conformité, l’efficacité opérationnelle et atteindre les objectifs en matière de consommation d’énergie, de durabilité environnementale et de bien-être social.

- En fournissant à ses fournisseurs un retour d’information et des critères de performance en temps utile, une marque peut les inciter à collaborer davantage et réduire son exposition aux risques.

Comment améliorer la transparence de la chaîne d’approvisionnement

1. Identifier les risques et fixer des objectifs

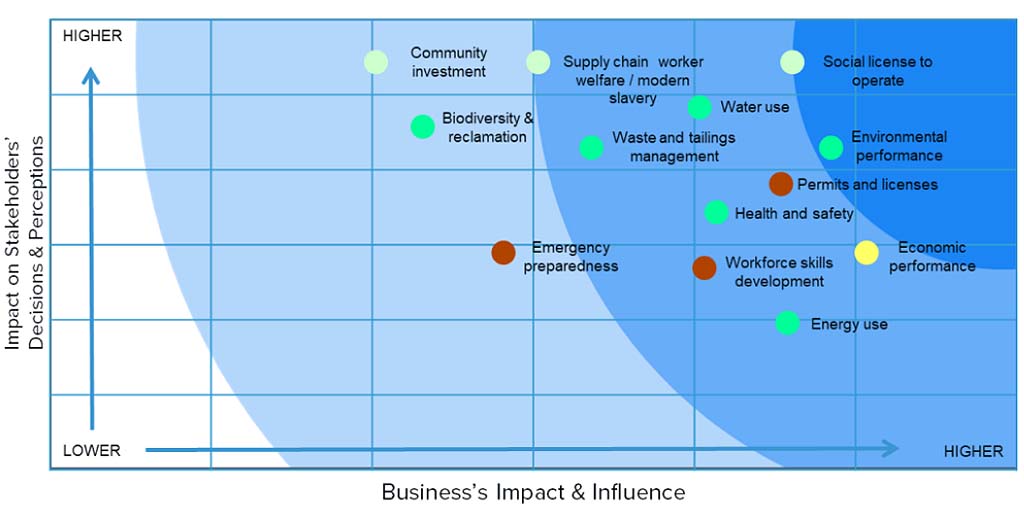

La première étape consiste à identifier les risques pour l’entreprise. La matérialité, comme on l’appelle, est une mesure de l’impact sur les performances financières ou opérationnelles de l’entreprise et sur les priorités des parties prenantes internes et externes. Une matrice de matérialité peut être utilisée pour aider à communiquer l’importance de chaque sujet à toutes les personnes concernées.

Une fois que les questions de matérialité sont comprises, l’entreprise peut définir des objectifs pour réduire les risques et stimuler les performances.

2. Visualisez votre chaîne de valeur

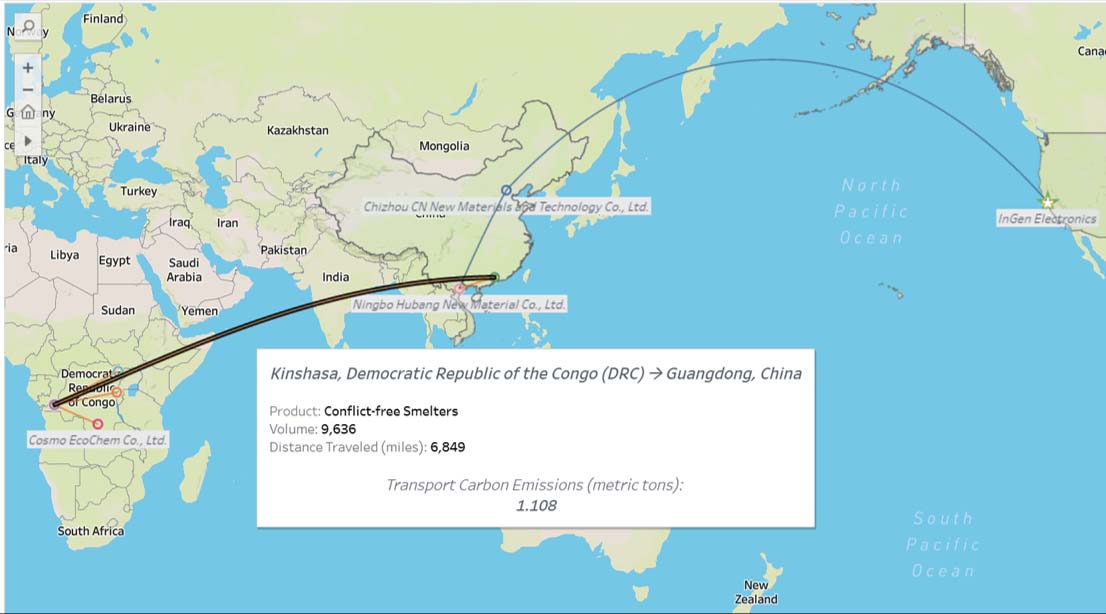

L’étape suivante consiste à mettre en place une représentation graphique de la chaîne de valeur afin de faciliter la compréhension et l’analyse pour soutenir la prise de décision. Les entreprises qui peuvent visualiser leur chaîne de valeur de bout en bout pourront mieux comprendre les flux de marchandises et de matériaux, identifier la concentration des fournisseurs et les risques liés à la localisation, suivre les émissions de carbone dues au transport et mettre en évidence les lacunes en matière d’information.

L’image ci-dessus illustre la chaîne de valeur de bout en bout d’une batterie de véhicule électrique, depuis les mines artisanales de cobalt jusqu’au site d’assemblage du véhicule. La cartographie de la chaîne d’approvisionnement s’est avérée importante pour les marques et les industries, telles que l’habillement et la fabrication de produits alimentaires, qui ont connu des problèmes dans la chaîne de valeur par le passé.

3. Collecter et gérer les informations

Pour cartographier la chaîne de valeur, les entreprises doivent collecter et consolider des données sur les transactions, les pratiques et les performances de leurs partenaires commerciaux, ainsi que sur les produits qui circulent entre eux. Cela implique des efforts et des coûts. Cependant, la valeur des données fournies est une vision permettant d’éviter les risques potentiels et des opportunités d’amélioration qui dépassent de loin le coût. Les entreprises se tournent de plus en plus vers leurs partenaires pour garantir le respect de toutes les exigences et comme source d’informations complètes et précises pour permettre la transparence de la chaîne de valeur. Des outils logiciels basés sur des plateformes sont nécessaires pour collecter et gérer les données de la chaîne d’approvisionnement, car la quantité de données est supérieure à ce que l’homme peut gérer seul. Ces applications permettent de visualiser la chaîne de valeur, de signaler tout problème ou problème potentiel, de mettre en place un processus d’action corrective et préventive (CAPA) et de favoriser la collaboration entre les parties prenantes.

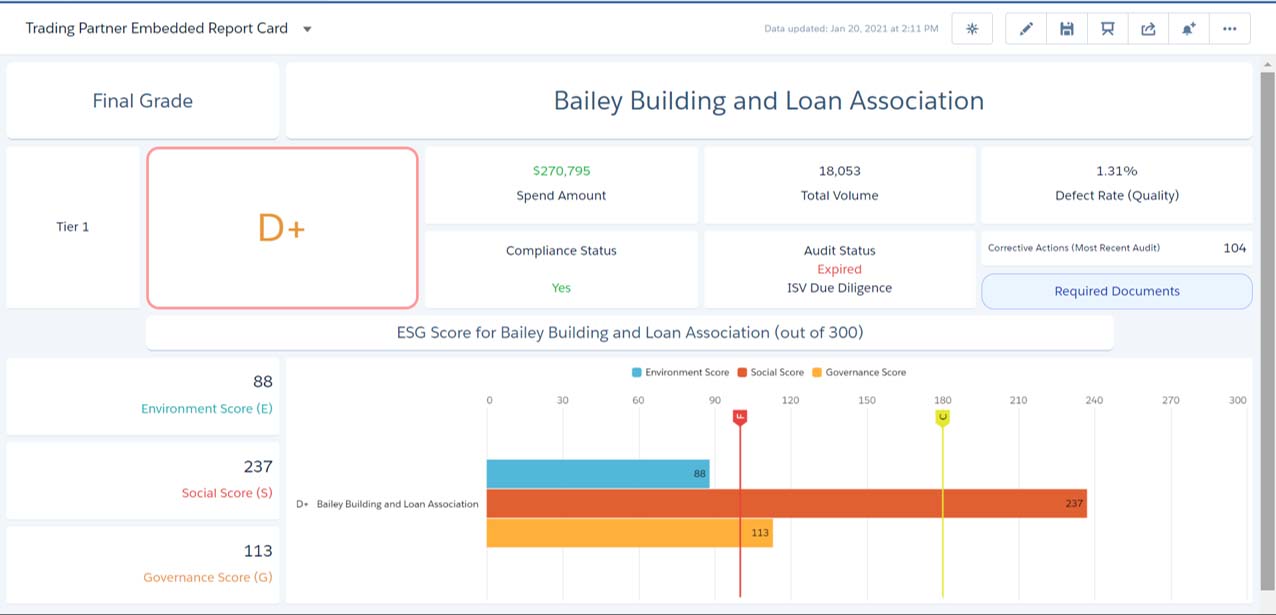

4. S’engager avec les parties prenantes

Munie d’informations et de connaissances, l’entreprise peut s’engager auprès de ses diverses parties prenantes. Il peut s’agir de programmes visant à améliorer les performances des fournisseurs, à atteindre les objectifs ESG, à gérer de manière proactive les relations avec les investisseurs et à sensibiliser les communautés. Pour les fournisseurs, les vendeurs et les fabricants sous contrat, etc., les entreprises devraient élaborer des tableaux de bord afin de suivre les mesures de performance et d’établir des comparaisons avec les pairs de la catégorie. Lorsqu’ils sont bien conçus, les tableaux de bord révèlent les fournisseurs à haut risque et les entreprises peu performantes, et permettent un suivi en temps réel pour atténuer l’exposition au risque.

5. Rendre compte et divulguer

Pour se conformer aux réglementations et aux exigences des investisseurs, les entreprises doivent développer leurs capacités en matière d’information non financière. Il s’agit notamment de décider comment répondre aux exigences réglementaires et aux demandes des parties prenantes en matière de perspectives et d’informations, et comment les informations essentielles seront vérifiées. Le développement des capacités de reporting demande des efforts et des coûts. Mais les avantages sont considérables. En effet, l’établissement de rapports est souvent un exercice annuel et, lorsque les rapports sont disponibles, les données qu’ils contiennent sont anciennes et ne sont plus exactes. La transparence de la chaîne d’approvisionnement, telle qu’elle est décrite dans ces étapes, permet de partager des informations plus récentes, ce qui peut avoir un impact important sur l’accès aux investisseurs et le coût du capital.

Pas de temps à perdre

Les pays s’apprêtent à mettre en œuvre des lois obligeant les entreprises à adopter des approches plus proactives pour garantir la transparence de leurs chaînes d’approvisionnement. Les étapes décrites ici sont continues car les chaînes d’approvisionnement et les risques évoluent. L’obtention et le maintien de la transparence de la chaîne d’approvisionnement est un processus très actif. Mais les avantages de la transparence de la chaîne d’approvisionnement se mesurent en termes de réduction des risques, de renforcement de l’engagement et d’augmentation de la productivité.